This month, those involved in the fashion industry witnessed first-hand how difficult it is to transition to sustainable clothing manufacturing methods. Stockholm based, award-winning textile recycling company Renewcell, has declared bankruptcy.

The news comes just over a year since the launch of their brand-new factory, which was built in November 2022, intending to double their production facilities from 60,000 tonnes to 120,000 tonnes of Circulose® pulp (recycled textile pulp, ready to be processed into fabric ).

The Swedish company, which has been in business for a decade, was at the forefront of efforts to scale up the supply of more sustainable materials in textile manufacturing.

What is the reason Renewcell declared bankruptcy?

Renewcell was a unique company that produced fabrics solely from recycled fibres. One might assume that this innovative approach alone would result in the company being the largest and most desired supplier for the major clothing brands worldwide.

However, the transition towards eco-friendly practises does not align with the principles of capitalism, where profit is the primary objective.

Brands are just not quick enough to transition from vertical to circular manufacturing processes.

February 25, 2024

“I regret to inform that we have been forced to take this decision to file for bankruptcy. As we have a strong belief in the company’s long-term potential, we have together with our advisors spent very substantial time and efforts into trying to secure the necessary liquidity, capital and ownership structure for the company to secure its future.

As part of the negotiations, we have had intense dialogues with both current main owners, new investors and our banks, as well as other stakeholders. However, these discussions have not been successful.

This is a sad day for the environment, our employees, our shareholders, and our other stakeholders, and it is a testament to the lack of leadership and necessary pace of change in the fashion industry.”

Michael Berg, Renewcell’s Chairman of the Board of Directors

Not receiving support from fashion brands

Fast fashion brands promised to buy more recycled fabrics from Renewcell and have been advertising that they are making efforts to offer more sustainable clothing.

In February 2020, H&M announced the creation of their first clothes collection in collaboration with Renewcell, aligned with “their vision to become fully circular”, Erik Karlsson, Investment Manager for Sustainable Fashion at H&M Group’s investment arm CO:LAB, had said in his statement.

Despite all the exciting headlines and promises from H&M and Inditex (owner of Zara) to continue supporting the circular fashion company, Renewcell announced in November 2023 that, unfortunately, no new orders had come through.

Sadly, this is not the first time we have seen fashion brands reluctant to invest in alternative, more environmentally friendly suppliers.

Investors eager for a quick return on their investment

Another significant challenge many innovative companies face is the expectation of swift profits from their investors.

Developing technologies and systems that support sustainable production takes more time to generate profits.

The eco-friendly industry is still in its infancy; therefore, adopting such complex systems is a slow process.

Any regenerative solution or solution prioritising the environment and the fair transition to sustainability offers long-term gains because it takes time to materialise.

Lack of infrastructure

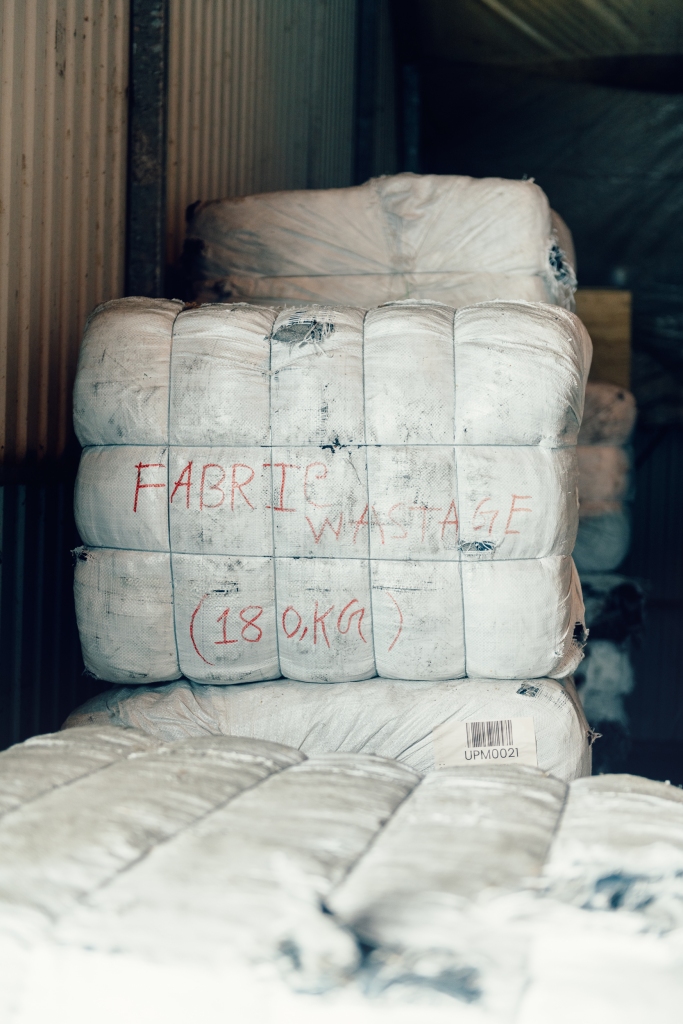

Renewcell’s production model was to source textile waste with a high cellulose content from factories that make denim and the second-hand clothing market. Renewcell developed technology that turns these materials into pulp (Circulose), which it sells to other companies that manufacture yarns to create fabrics through a network of over 150 suppliers.

These suppliers had to cover the significant investment cost to convert their existing machinery to be capable of processing the recovered fibre pulp.

Likewise, the lack of domestic infrastructure in all circular fashion processes (collection, sorting and processing of discarded clothing from landfills to put them back to the production process) is a significant barrier to circular textile efforts.

It requires a mutual effort by policymakers, research and development departments and the stakeholders in the circular textile industry.

As a result, the given cost of recycling the clothes into a pulp in the first place, in addition to the special processing, contributed to the high prices of the final product (fabric).

Fast-fashion companies that charge consumers less than the cost of a coffee for trendy outfits are seeing recycled fashion reach buyers considerably more expensive.

Due to fear of decreased sales and decision-making depending on their shareholders’ profits, brands choose to offer limited lines of sustainable clothing collections.

This practice allows them to be seen as ‘working towards a more environmentally friendly’ solution, avoiding the risk of radically changing their business model.

Lack of legal framework

As mentioned, the dominant economic system is based on profit over social and environmental benefits. Large businesses grow in a fiercely competitive environment.

Therefore, the state has limited opportunities to create legal frameworks that require firms to invest in sustainable technologies and take responsibility for the integrated process of production, supply, and recovery of their products when they have reached the end of their use/life, returning them to the production process ( circular economy).

As a result, any changes are left to the fashion brands’ managing directors, who, as mentioned above, are reluctant to change their business model from the outset.

The delay in embracing strategies for an environment-first economy and fair compensation for workers, where the fashion industry is required to take full responsibility for its products from the outset, is effectively proving disastrous for companies like Renewcell.

Winds of change

The fashion industry produces 10 percent of humanity’s carbon emissions, according to UNEP.

It contributes significantly to the degradation of the environment because it uses huge amounts of water resources and toxic chemicals to create fabrics.

Discarding unwanted clothing adds to landfill waste, and the chemicals are absorbed into the soil, poison the environment and crops.

These businesses make huge profits because they are partially responsible for the clothes they create. As with other businesses, once the clothes/products leave the shops, consumers and the government (which is funded by consumers through taxes, of course) bear the burden of disposal, possible recycling of the fabrics and make good the environmental damage.

For companies like Renewcell to thrive, policymakers, investors, manufacturers, and fashion brands must take collective action to embrace sustainable solutions that will become mainstream.

Hopefully, the company will secure new investors who will help revitalise this groundbreaking initiative and accelerate the transition to a more sustainable fashion industry.

Update March 15, 2024:

Renewcell Expands Timeline to Receive Bids

In a recent update, Renewcell’s bankruptcy trustee extended the deadline for receiving purchase offers to 28 March to accommodate bids from several companies. The trustee anticipates a new owner will be secured in early April and will be announced shortly after that.

Hopefully, a viable offer will be secured for Renewcell in the end, making the incident a wake-up call for all stakeholders in the fashion industry.

You must be logged in to post a comment.